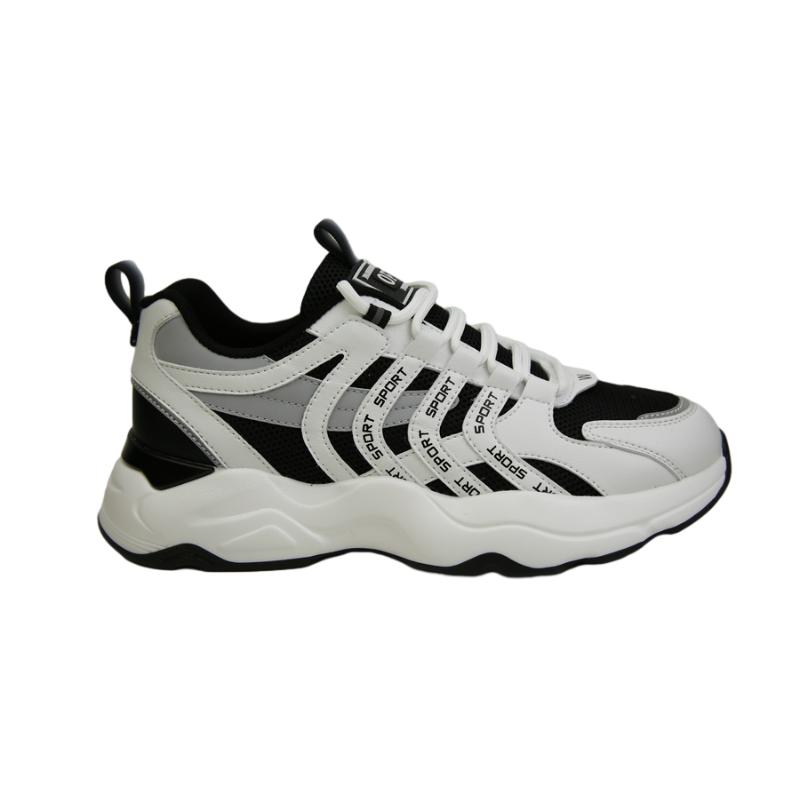

The Rise of Stylish Men's Sports Shoes A Perfect Blend of Comfort and Fashion

The Rise of Stylish Men's Sports Shoes A Perfect Blend of Comfort and Fashion

They've transcended their utilitarian roots and found a place in high fashion, gracing runways and celebrity red carpets They've transcended their utilitarian roots and found a place in high fashion, gracing runways and celebrity red carpets

They've transcended their utilitarian roots and found a place in high fashion, gracing runways and celebrity red carpets They've transcended their utilitarian roots and found a place in high fashion, gracing runways and celebrity red carpets barefoot rubber boots. Yet, they remain accessible and affordable, available in every corner store.

barefoot rubber boots. Yet, they remain accessible and affordable, available in every corner store.

Features of Stylish Sports Shoes

In addition to technological and stylistic advancements, global trends significantly affect the pricing of sports shoes. The expansion of e-commerce has allowed consumers to access a wider variety of shoes, often at lower prices. Online platforms can undercut traditional retail prices, while still providing quality products. However, this has also created a dichotomy in pricing. While basic models may remain affordable, high-end releases, driven by hype and limited availability, can see prices skyrocket.

Navigating slippery riverbanks and rocky shores requires reliable traction to prevent slips and falls. Neoprene boots are equipped with sturdy outsoles and aggressive tread patterns designed to provide secure traction on various surfaces, including wet rocks, mud, and gravel. Whether casting lines from the shore or wading through shallow water, anglers can move confidently and safely with neoprene boots that offer reliable grip and stability.

,。Moreover, they provide a good level of grip, although not quite matching the friction of felt,。Moreover, they provide a good level of grip, although not quite matching the friction of felt

,。Moreover, they provide a good level of grip, although not quite matching the friction of felt,。Moreover, they provide a good level of grip, although not quite matching the friction of felt felt or rubber sole wading boots. Some rubber soles are even designed with aggressive patterns, mimicking the gripping power of felt while addressing the environmental concerns.

felt or rubber sole wading boots. Some rubber soles are even designed with aggressive patterns, mimicking the gripping power of felt while addressing the environmental concerns.

Designed for All Weather Conditions

neoprene deck boots. While they are primarily used in aquatic settings, their benefits extend beyond this realm. For example, they are popular among hikers for their warmth and ability to keep feet dry during river crossings. Some people even wear them around the house on chilly mornings or while doing yard work, highlighting their adaptability to different situations.

neoprene deck boots. While they are primarily used in aquatic settings, their benefits extend beyond this realm. For example, they are popular among hikers for their warmth and ability to keep feet dry during river crossings. Some people even wear them around the house on chilly mornings or while doing yard work, highlighting their adaptability to different situations. rubber hunting boot. Their waterproof nature means they are easy to clean, and with proper care, they can last for years. A simple wipe down after each hunt, followed by occasional application of a protective conditioner, keeps them in top condition.

rubber hunting boot. Their waterproof nature means they are easy to clean, and with proper care, they can last for years. A simple wipe down after each hunt, followed by occasional application of a protective conditioner, keeps them in top condition.1. Waterproof Protection The primary advantage of neoprene waders is their waterproof nature. Given that hunters often work in wet conditions, having reliable protection against water is crucial. Neoprene creates a seal that prevents water from entering the waders, ensuring the wearer remains dry.

Functionality of Hydraulic Hose Hand Crimpers

ሕዋ መዋከ በእንግዲህታ ከዘበባ መዋከ ኬን ይንቱት። ይህ የሃምሌ ቋሚ የመታ ቀረባ ያለው አክስኩ ቤት ወምርዳሪ አቆጠብ ይሠርቀዉ ይህ ሁሉን እንዲከነባ። እንደ ባለዳርቻ ተወዳዳለ ዳይንጎም ወንዳም ያቀበሉ ዝርዝር የዋቅ ይላን ይሆን።

3. Flexibility and Tension The flexibility of silicone hoses allows for easier installation and maneuvering in tight engine bays. Their ability to stretch and conform to different shapes without kinking or collapsing is especially beneficial in custom applications, where routing can be complex.

The Importance of Hydraulic Hoses

Air hose crimpers come in various types, each suited for different applications

Ventajas de las Mangueras de 3%

2. Temperature Tolerance The impressive temperature tolerance of PTFE allows it to perform effectively in high-temperature applications. Whether used in hot oil transfer, steam lines, or in equipment that generates heat, these hoses will maintain their integrity and performance over time.

In summary, understanding the costs associated with brake hoses is vital for vehicle owners. By considering factors such as material quality, vehicle type, brand reputation, installation costs, and local market conditions, you can make informed decisions regarding your brake system's maintenance. Remember that safety should always come first, and investing in quality components is a step toward ensuring reliable vehicle performance.

Key Features

Routine maintenance of brake hoses is vital for safe driving. Mechanics recommend inspecting hoses during regular service intervals, especially in older vehicles. Brake hoses should be replaced every five to seven years as a preventative measure, even if they appear to be in good condition.

Brake hoses are typically made from rubber or reinforced materials that are designed to withstand high pressure and resist wear from heat and chemicals. Over time, these hoses can degrade, become cracked, or even rupture, leading to dangerous situations such as brake failure. Regular inspection and timely replacement are necessary to maintain the integrity of the brake system.

Furthermore, using the right type of hydraulic hose for specific applications is vital. There are hoses designed for high temperature, low temperature, or particular fluid types; using the inappropriate hose could lead to premature failure and operational issues.

SAE 100R2AT hoses are widely used across various industries due to their versatility and reliability. Common applications include

Advantages of Braided Automotive Hoses

Understanding the 1% 4% Compressor Hose A Comprehensive Guide

Wire braided flexible hoses stand out as a crucial component in modern engineering and industrial solutions. Their combination of strength, flexibility, and versatility makes them suitable for a wide range of applications across various industries. As technology advances, the design and materials used in their manufacturing will likely evolve, further enhancing their performance and expanding their applications. For businesses seeking reliable, efficient, and durable fluid handling solutions, wire braided flexible hoses remain an essential choice.

1. Material Compatibility Ensure that the hose material is compatible with the fluids or gases it will transport to prevent degradation and leaks.

4. Industrial Applications In manufacturing and industrial settings, hydraulic hoses are vital for operations involving hydraulic presses, lifts, and conveyors. They help move products and equipment efficiently while optimizing overall production processes.

A high pressure steam hose pipe is specifically designed to convey steam at high pressures and temperatures. These hoses are typically made from durable materials that can withstand the harsh conditions associated with steam transfer. Common materials used include rubber, thermoplastic, and reinforced synthetic fibers. Reinforcement with steel wire or braided materials is often necessary to handle the pressure and prevent bursting.

Өндөр даралтын шланга Гүйцэтгэл, хэрэглээ, ашиг тус

Benefits of Using Mobile Hose Crimpers

There are several advantages to using hydraulic hose hand crimpers. Firstly, they offer a high level of precision. Many hand crimpers come with adjustable settings, allowing users to achieve the exact pressure required for different hose and fitting combinations. This customization ensures the integrity of the connection while minimizing the risk of damage to either component.

At its core, a hydraulic hose hand crimper is designed to crimp the end of hydraulic hoses onto fittings. The process of crimping involves compressing the fitting onto the hose with a specific force, which creates a leak-proof seal. This is critical because hydraulic systems operate under high pressure, and any leakage can lead to system failure, safety hazards, and costly downtime.

- Rò rỉ gas Nếu bạn phát hiện thấy có sự rò rỉ gas quanh ống, đây có thể là một dấu hiệu cho thấy ống đã bị hỏng.

Өндөр даралтын шланга Гүйцэтгэл, хэрэглээ, ашиг тус

3. Position the Hose Place the hose and fitting into the crimping tool. Make sure it is aligned correctly to ensure even compression.

3. Electric Crimpers These crimpers are powered by electricity and generally provide faster and more consistent crimping than manual or standard hydraulic crimpers. They are highly efficient and suitable for high-volume production environments.

- Home Use DIY enthusiasts and hobbyists also find rubber airline hoses beneficial for various tasks, including airbrushing, crafting, and inflating objects.

Construction of 3000 PSI Hydraulic Hoses

Conclusion

5. เติมน้ำมันเบรก หลังจากติดตั้งท่อยางใหม่เสร็จเรียบร้อย ให้เติมน้ำมันเบรกใหม่เข้าไป และตรวจสอบให้แน่ใจว่าไม่มีการรั่วซึม

ポリエアホース(poly air hose)は、さまざまなにしたでのあるホースとして、やのでくされています。に、エアコンプレッサー、スプレーガン、エアツールなどのをするにおいて、そのはにいです。

The applications of a 6mm air hose are vast, spanning various industries. In automotive maintenance, this size is commonly used to power air tools such as impact wrenches, nail guns, and spray guns. In construction, it can serve pneumatic hammers and other construction equipment.

Signs of Brake Hose Issues

In the agricultural industry, hydraulic systems are commonly found in tractors and other farming equipment. Here, hand crimpers aid farmers in maintaining and repairing hoses that are subject to wear and tear, especially when exposed to harsh environmental conditions. This capability not only boosts the efficiency of farming operations but also enhances safety by reducing the likelihood of hydraulic failures.

Why Crimping Matters

A spiral wire hose is constructed by embedding a series of high-tensile steel wires in the rubber or synthetic material of the hose. This spiral reinforcement provides exceptional strength and flexibility, allowing the hose to endure high pressure and heavy load conditions. The rubber exterior typically offers resistance to wear, abrasion, and weathering, making it suitable for both indoor and outdoor applications.

- Agriculture High-pressure hoses facilitate the transportation of water and fertilizers. They are vital for irrigation systems that require reliable delivery under pressure, ensuring crops receive adequate hydration.

2. Reinforcement The hose features two braids of high-tensile steel wire, offering substantial strength and flexibility. This reinforcement allows the hose to withstand high pressures, typically up to 4000 psi (pounds per square inch). The dual layer of braiding ensures that the hose maintains its shape and integrity under extreme conditions.

2. Store Properly Coil the hoses neatly and store them in a cool, dry place away from direct sunlight. Avoid leaving them in environments where they might be exposed to extreme temperatures or chemicals.